Photoelectric Sensors Applications Types and Benefits

Photoelectric Sensors: Understanding Applications, Types & Benefits

Photoelectric sensors, with their diverse applications, types, and significant benefits, play a crucial role in industrial automation and safety. These essential components detect the presence or absence of objects, measure distances, and ensure precise operations across various settings. Indeed, this post explores the fundamentals of these sensors, their different types, and the significant advantages they offer in a wide range of industrial applications.

What Are Photoelectric Sensors?

Photoelectric sensors use light to detect objects or measure distances. These devices emit a light beam—typically infrared or visible. Then, they measure the reflection or interruption of the beam to determine an object’s position or status. Ultimately, they are vital in many industrial applications where precision is key.

Types of Photoelectric Sensors

Photoelectric sensors come in various types, each suited for specific tasks. Here, let’s explore the three most common types:

Through-Beam Sensors

These sensors consist of a separate emitter and receiver positioned opposite each other. An object’s presence is detected when it interrupts the light beam between them. This setup is reliable for long-range detection. Therefore, it is ideal for applications where the object moves over a greater distance.

Retro-Reflective Sensors

In this configuration, both the emitter and receiver reside in a single unit. A reflector is placed opposite the sensor. The sensor detects an object’s presence when it reflects the emitted light back to the receiver. These sensors are useful for shorter detection ranges, making them a good choice for compact spaces.

Diffuse Sensors

With diffuse sensors, the emitter and receiver are combined into one unit. These sensors detect objects based on the light reflected off the object’s surface. This type is highly versatile. Consequently, it is ideal when the object’s distance can vary, offering reliable performance in diverse settings.

Applications of Photoelectric Sensors

Photoelectric sensors find widespread use across various industries. Specifically, here are some key applications:

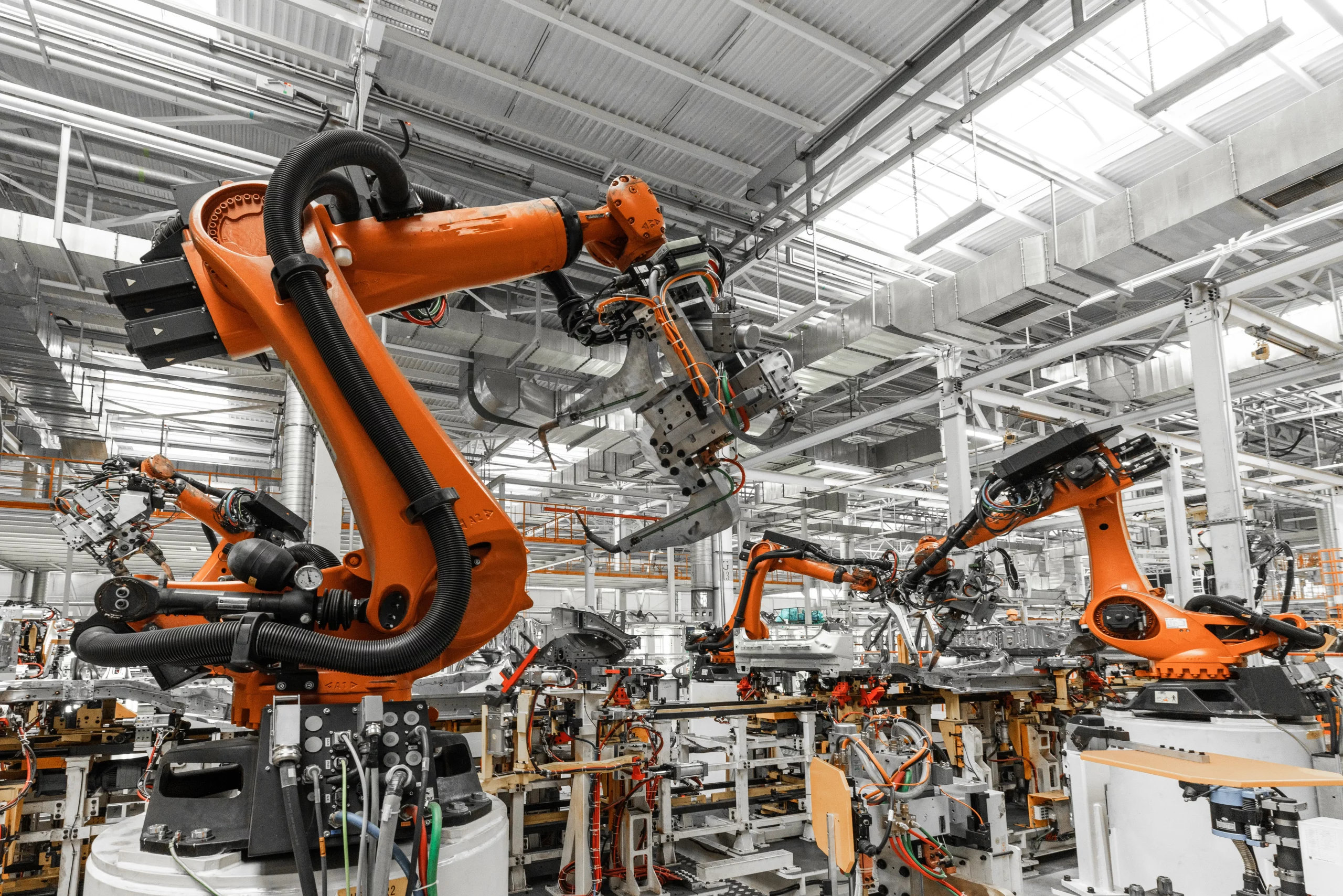

Automation

In manufacturing and assembly lines, photoelectric sensors ensure objects are correctly positioned for further processing. They play a crucial role in conveyor systems, robotic operations, and quality control. For more insights into industrial automation, you can explore resources like [this external automation industry guide](https://www.google.com/search?q=https://www.example.com/automation-guide – Replace with actual link).

Safety Systems

Photoelectric sensors are employed in safety barriers and gates. They detect when someone or something crosses a designated line. Upon detection, they trigger alarms or stop machinery to prevent accidents, thus enhancing workplace safety. Learn more about industrial safety standards from reputable organizations such as [OSHA](https://www.osha.gov/ – Replace with actual link).

Object Counting and Sorting

In packaging and sorting systems, photoelectric sensors count items or sort them based on size, shape, or color. They streamline operations and improve the accuracy of these processes.

Distance Measurement

These sensors also play an essential role in measuring distances. For example, they detect material levels in tanks or silos, where precision is critical to maintaining smooth operations.

Benefits of Using Photoelectric Sensors

Photoelectric sensors offer numerous advantages that improve efficiency and safety in industrial applications:

Non-Contact Detection

Since photoelectric sensors do not require physical contact with objects, they minimize wear and tear. Moreover, this results in fewer maintenance requirements and a longer sensor lifespan.

High Precision and Reliability

These sensors deliver accurate detection and measurement. This is true even in challenging environments such as extreme temperatures, dust, or moisture.

Versatility

The availability of different photoelectric sensor types allows their adaptation for a wide variety of applications. This includes simple detection tasks to complex automation systems.

Ease of Integration

Photoelectric sensors are compatible with most automation systems. Their seamless integration into existing setups makes them a practical choice for upgrading or optimizing industrial operations.

Why Buy from Balkan Automation 24

At Balkan Automation 24, we offer a curated selection of high-quality sensors, including photoelectric sensors, from trusted manufacturers. Our products are known for their durability, precision, and reliability, ensuring long-term performance even in the most demanding environments. Shopping with us means you’ll receive:

- Expert guidance to help you choose the right products.

- Competitive pricing to fit your budget.

- Fast and secure shipping to your location.

Conclusion

In contemporary industrial settings, photoelectric sensors play a vital role in both automation and safety protocols. Gaining a thorough understanding of the various types available, their practical applications, and the advantages they offer enables companies to significantly streamline workflows, boost safety standards, and enhance overall operational effectiveness. Whether the goal is automating a manufacturing line or ensuring personnel security in the workplace, these sensors provide accurate and dependable answers. Therefore, consider exploring the potential benefits these sensors bring to your processes and integrating them to achieve superior operational performance and enhanced safety levels.

Find and explore the comprehensive range of these SIPLUS industrial components at balkanautomation24.com. For detailed information, product inquiries, or expert technical support tailored to demanding applications, contact our expert team through the website.